Techniques

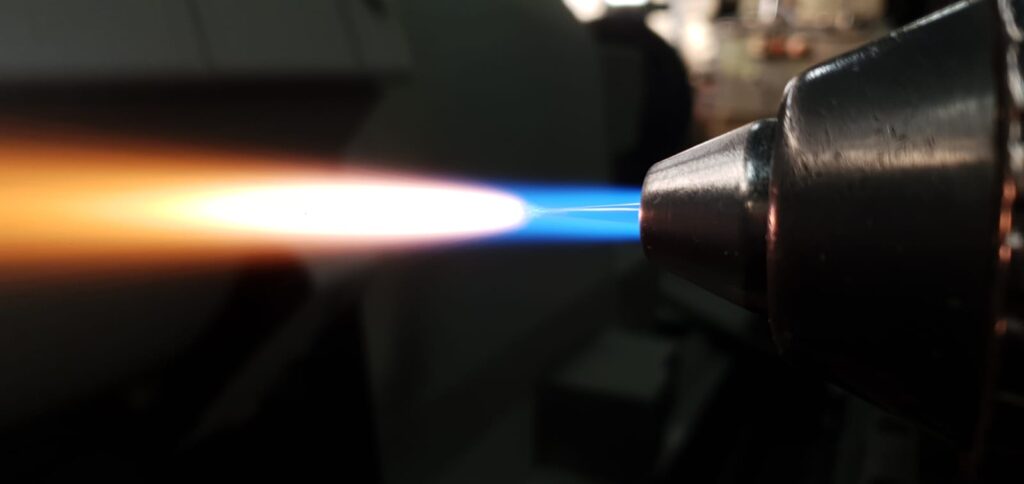

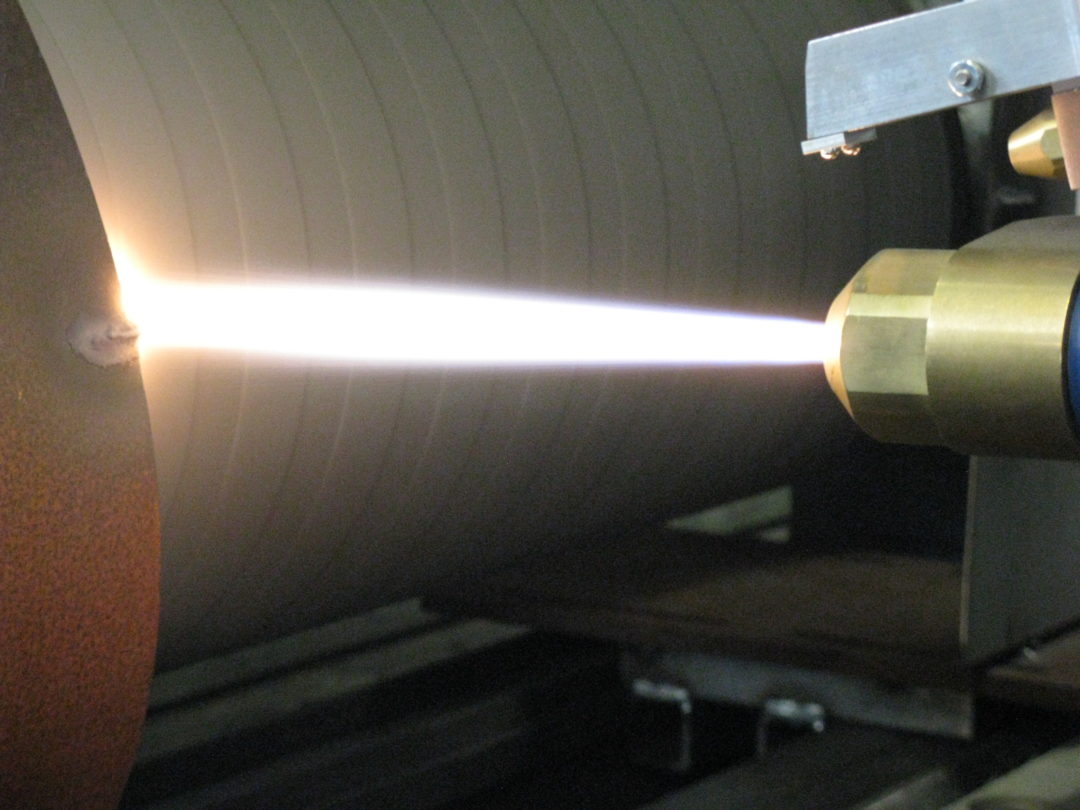

Thermal spraying is a collective term for processes in which a metal, a metal alloy or metal compound in wire or powder form is made plastic by means of a heat source and applied to the workpiece with a lot of kinetic energy.

In this way a coating can be obtained with greatly improving properties for the function of the machine part. The selection of the coating to be applied can be determined more or less independently of the underlying material, so that the most optimal properties can be added to the part.

Thermal spraying is a so-called cold process and can be applied to virtually any surface. Regardless of the heat source, the base material does not heat up more than 100°C, so that no structure and/or shape change occurs. The applied coating has a lamellar structure (lamellar structures or microstructures are composed of fine alternating layers of different materials in the form of lamellae) which are mechanically connected to the substrate.

An exception to this is the group of melt-in alloys that receive an additional post-treatment, whereby the coating becomes homogeneous in structure at a temperature of 1.060°C and is atomically bonded to the substrate.

Spraying processes

Industries

Industry is the part of the economy characterized by the production and processing of material goods or articles in factories and enterprises.

Since 1978 Plasma Service has proven to be a very reliable partner for many industry groups. With our fully equipped machine factory and our specialization in applying thermal spray layers, we can copy, improve and repair parts.

Solutions

Plasma Service’s spraying techniques can be used both preventively and for repair. In this section you will find some examples of parts covered by our processes. This can be a custom repair but also an improvement of tool life. So we can add properties that it doesn’t have originally.