Wire spraying

Autogenous wire spraying or wire flame blowing is the oldest process in thermal spraying technology.

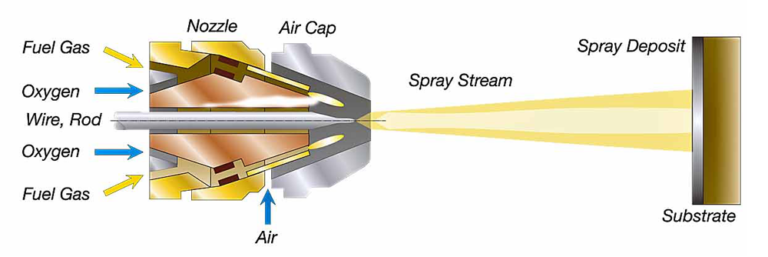

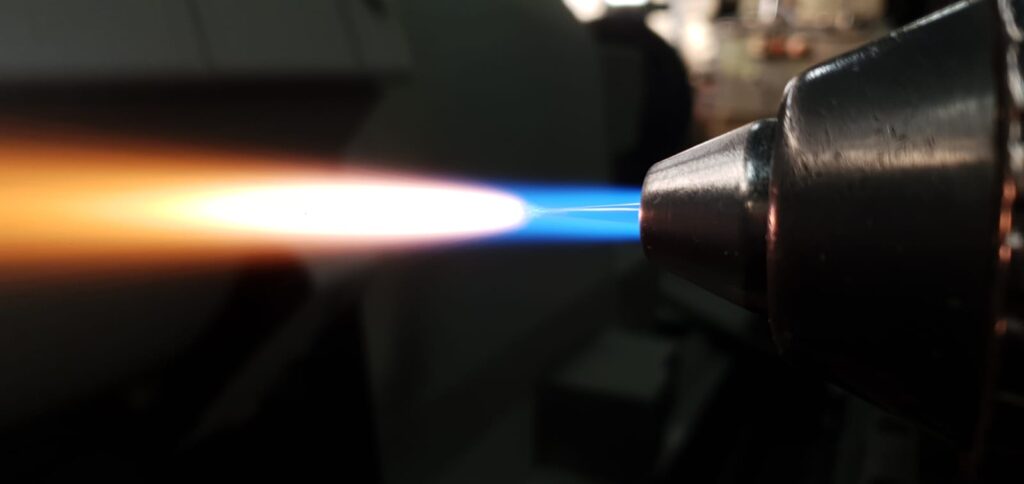

By means of an electric motor or an air motor, a material in wire form is transported through a spray gun and melted centrally in a burning gas-oxygen mixture (usually acetylene-oxygen). Subsequently, the molten material is atomized to the substrate by means of compressed air to form a coating there.

The materials to be sprayed for this process are metals and alloys that can be drawn into wire form and have a melting point well below the temperature of the heat source used. When zinc or aluminum is used for the wires, autogenous wire spraying is also called Schoopen, after the name of the inventor.

Applications

- Piston rings with molybdenum for wear resistance and better running properties (reduction of friction coefficient)

- Corrosion protection of locks and/or bridges with aluminium, zinc and their alloys

- Repairs or dimensional corrections of run-in shaft journals or bearing seats with stainless steel alloys

- Plain bearing surfaces with white metal (Babbitt) or Bronze

- Electrical shielding with tin or zinc

Positive features

In this way it is possible to apply a coating at relatively low cost. Due to the availability of simple spray materials, this technique is ideally suited for bringing worn parts back to standard size.

Applicable materials (DIN EN ISO 14919)

- Chrome steel

- Stainless steel

- Monel

- Copper

- Aluminium

- Bronze

- Molybdenum

How can we be of service to you?

Do you have a question? Please contact us by filling in the contact form.