Electric Spray

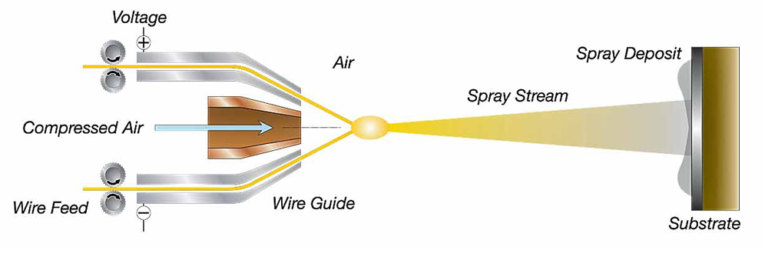

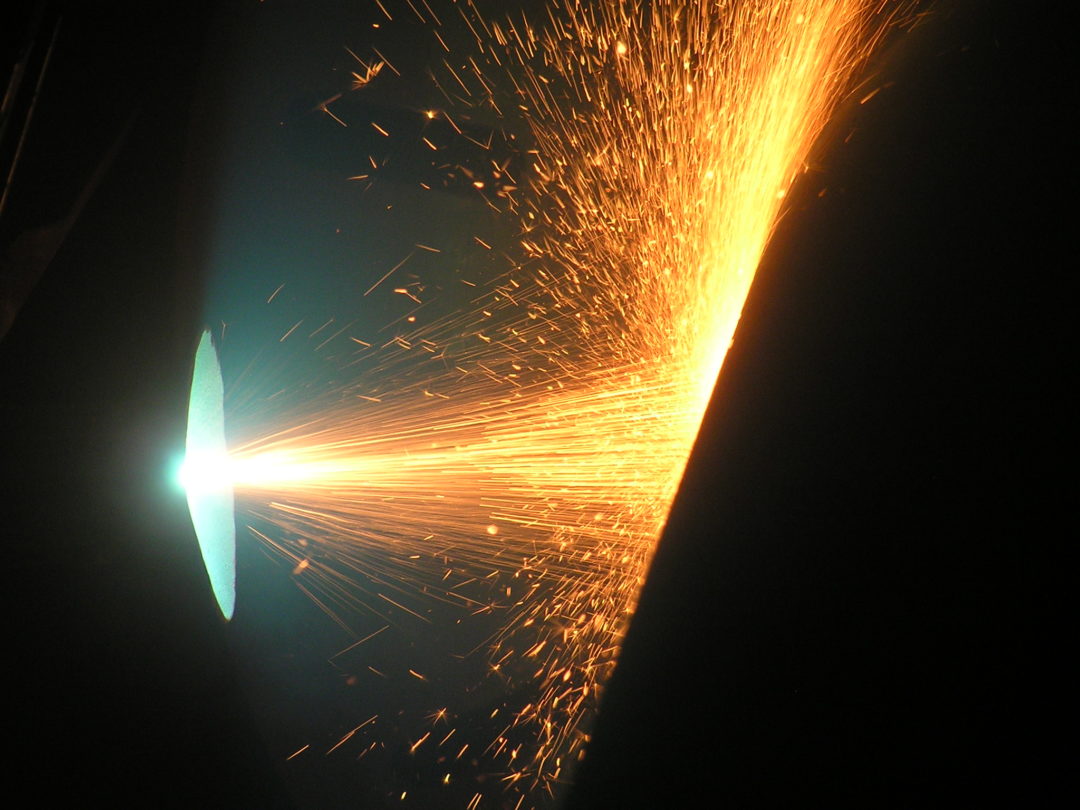

Electric wire spraying, also called ARC wire spray, is a technique in which two electrically conductive materials are transported through a spray gun. An electric arc is drawn between the ends of these wires, causing them to melt. The molten material is transported to the workpiece by compressed air.

The arc temperature of approximately 4,000°C gives a greater spraying capacity and adhesion compared to autogenous wire spraying.

Electric wire spraying is one of the cold spraying processes. This means that the workpiece does not get hotter than 100 to 150°C. As a result, the dimensions of the part are preserved and no structure changes occur in the base material.

One of the advantages of this system is that two different wires can be used simultaneously to produce a pseudoalloy. Cored wires are also available that produce coatings with unique properties.

With this process, coatings can be applied quickly and at low (energy) costs. The equipment can operate at low energy costs, while the mobility of the equipment is high, making the process suitable for working on site.

Applications

- Boiler walls of incinerators against high temperature erosion and chemical attack

- Repairs or dimensional corrections of run-in journals or bearing seats with nickel base alloys

- Corrosion protection of locks and/or bridges with aluminium, zinc and their alloys

- Electrical shielding with tin or zinc

- Anti-slip and traction coatings (coarse layers)

Positive features

With this process, excellent coatings can be applied quickly and at low cost.

It is therefore particularly suitable for larger coating surfaces, while the layer thickness can be more than 15 mm.

Applicable materials (DIN EN ISO 14919)

- Chrome steel

- Stainless steel

- Bronze

- Pseudo-alloys

How can we be of service to you?

Do you have a question? Please contact us by filling in the contact form.