Hard Chrome Replacement

Traditionally, chromium or nickel are applied by electroplating. The basis of a hard chrome treatment is chromic acid (Chromium trioxide, a chromium-6 compound), and has been on the Reach list since 2014, a list of hazardous substances.

The purpose of hard chrome plating is to increase corrosion resistance, hardness and wear resistance for various applications:

- Shock absorbers

- Pumps

- valves

- ball bearings

- Injection Systems

The limited choice, continuous porosity and limited layer thickness give your part a limited life.

Environmentally responsible alternative

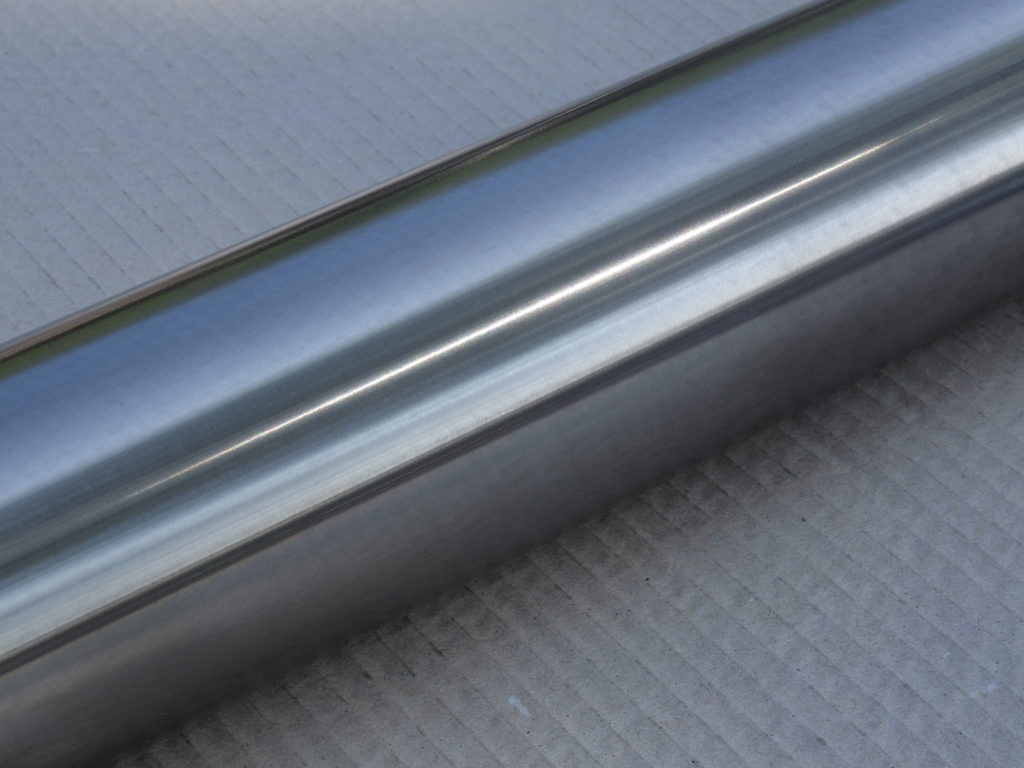

By using a thermally sprayed coating from Plasma Service, you get a coating that has a higher corrosion resistance and wear resistance compared to traditional chromium or nickel layers. The environmental impact is also virtually zero because we do not use chromic acid. Also, virtually no chromium-6 is released during this process.

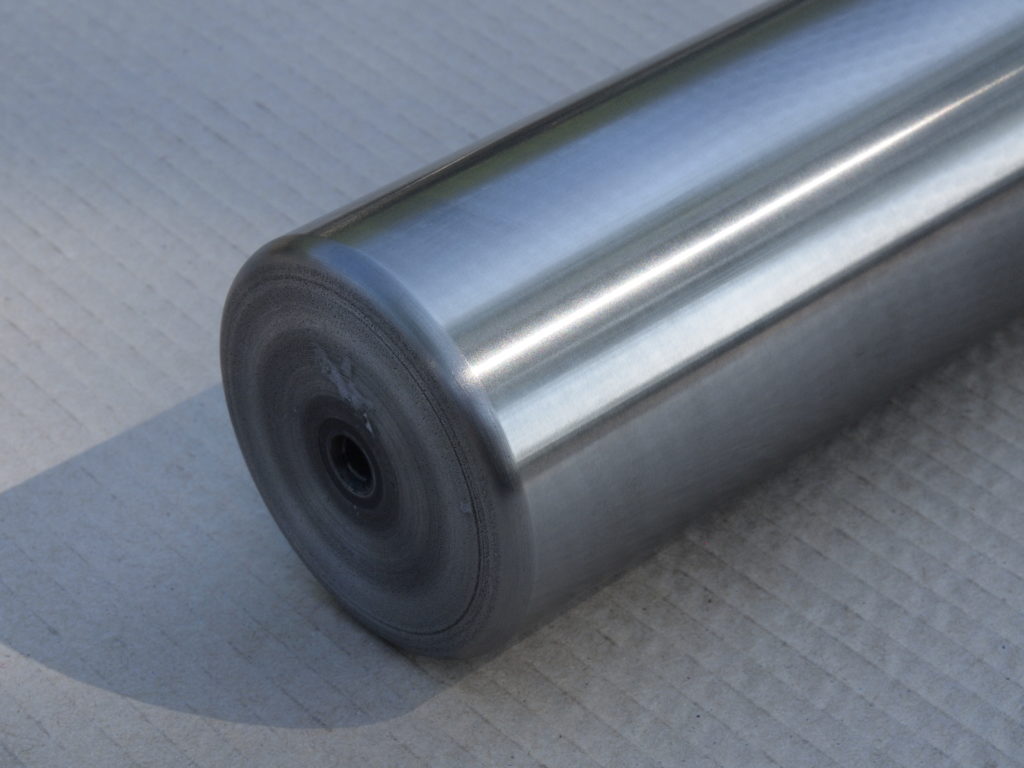

So give new or existing piston rods, plungers or other (hard) chrome parts a longer lifespan or a second chance by having them treated by Plasma Service with a hard chrome replacement.

Additional Advantages

- There is no hydrogen embrittlement in the base material

- No (extra) heat treatment is required

- Hard chrome plating reduces the fatigue strength, with thermal spraying the fatigue strength can sometimes be positively influenced

Expense

OEM suppliers often charge exorbitant amounts for new genuine parts for their machines. As a customer, you often have no other options because it simply does not fit your configuration.

For a fraction of the new value, Plasma Service ensures that your rotating parts are as good as, or often even better than, new.

Sustainability

If something breaks or you have damage, the first thought is quickly to buy it new. By repairing the part or providing it with a preventive coating, the burden on the environment is reduced. An additional advantage is that repair is faster than manufacturing a new part.

How can we be of service to you?

Do you have a question? Please contact us by filling in the contact form.