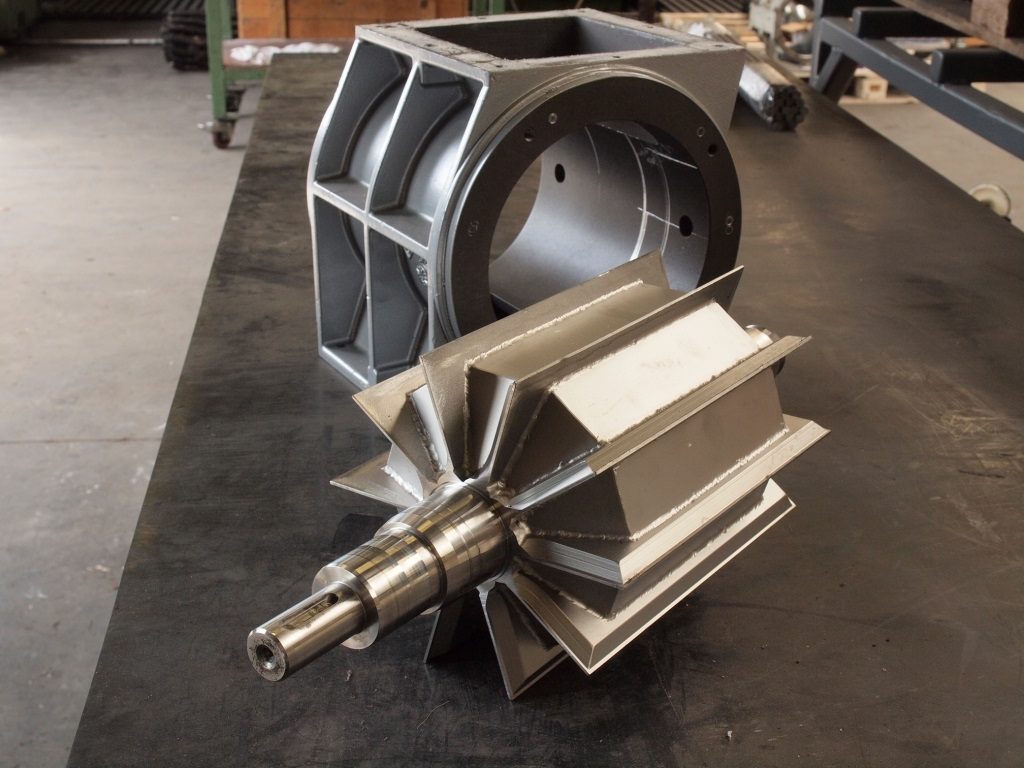

Rotary Valves

We repair rotary valves, also known as rotary valves or excavator wheel locks, in various industrial groups.

These locks are often used to regulate powder and dust flows when using trapdoors, silos and screw conveyors. Wear from the medium and added air transport can cause premature wear and leakage.

Depending on the size and application, rotary valves can have a significant purchase price and delivery time. We offer an alternative for companies with rotary locks: the repair of lock housing, rotor and covers. After disassembly, cleaning, entry check and analysis, you will receive tailor-made advice for the repair and/or preventive treatment of your vital equipment.

Some examples

- Alignment and repair of clutch ball bearing and seal fits

- Tailor radial and/or axial blades, increase hardness and wear resistance

- Machining the housing and both lids to size and coating wear-resistant by means of thermal spraying

- Assemble completely according to specifications

Your advantage

- No long delivery times

- Preventive treatment to extend the stand time

- Complete overhaul for a 2nd or 3rd lifespan

- Reducing your total costs

Expense

OEM suppliers often charge exorbitant amounts for new genuine parts for their machines. As a customer, you often have no other options because it simply does not fit your configuration.

For a fraction of the new value, Plasma Service ensures that your rotating parts are as good as, or often even better than, new.

Sustainability

If something breaks or you have damage, the first thought is quickly to buy it new. By repairing the part or providing it with a preventive coating, the burden on the environment is reduced. An additional advantage is that repair is faster than manufacturing a new part.

How can we be of service to you?

Do you have a question? Please contact us by filling in the contact form.