Compressors

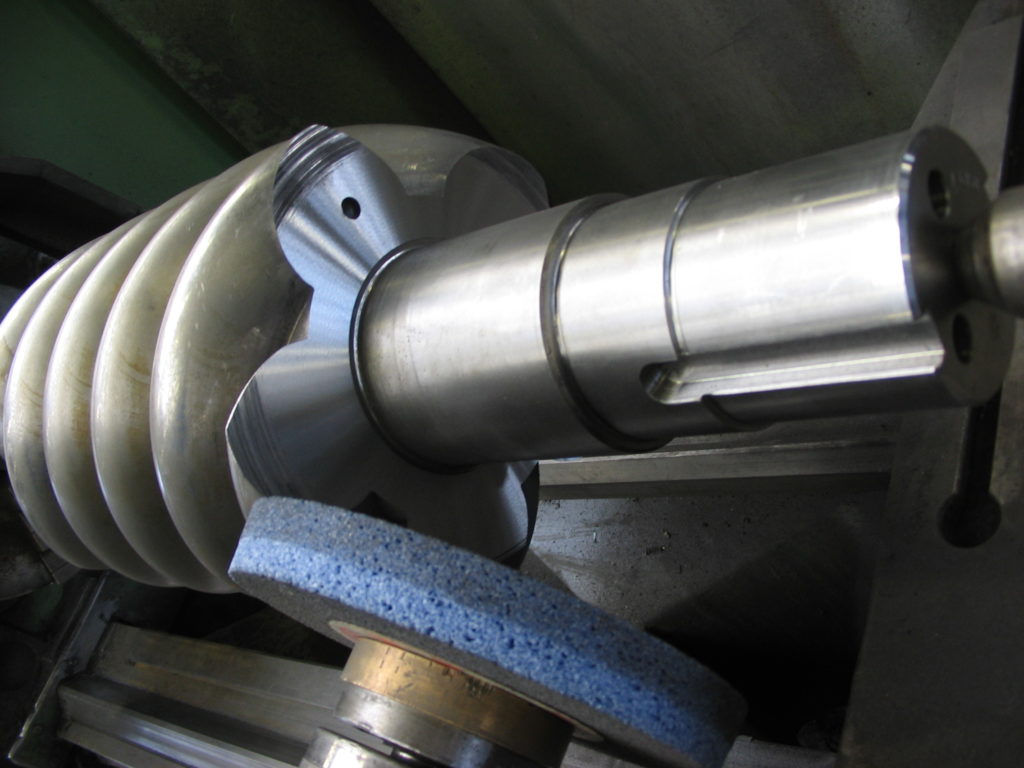

A screw compressor or twin-screw compressor is used to compress gases. A screw compressor consists of a housing containing two rotors with a screw profile (m/f). When the rotors start to rotate, the gas between these rotors is compressed. The whole of housing and rotors is called element. Depending on the desired final pressure, several elements can be used in series. An intercooler is then provided between these elements to lower the inlet temperature of the gas to the second element.

Compressors are at the heart of your company. Downtime is often very expensive and repairs often take too long. Your supplier usually repairs your system with new expensive parts. This is usually unnecessary.

By using thermally sprayed coatings from Plasma Service, you have the opportunity to repair undersized and/or worn fits at reduced costs.

So give your existing worn compressor parts a second chance by having them repaired.

Advantages

- Repair is often cheaper than new

- Better for the environment

- Recovery is often faster than a new one

Expense

OEM suppliers often charge exorbitant amounts for new genuine parts for their machines. As a customer, you often have no other options because it simply does not fit your configuration.

For a fraction of the new value, Plasma Service ensures that your rotating parts are as good as, or often even better than, new.

Sustainability

If something breaks or you have damage, the first thought is quickly to buy it new. By repairing the part or providing it with a preventive coating, the burden on the environment is reduced. An additional advantage is that repair is faster than manufacturing a new part.

How can we be of service to you?

Do you have a question? Please contact us by filling in the contact form.