HVOF spraying

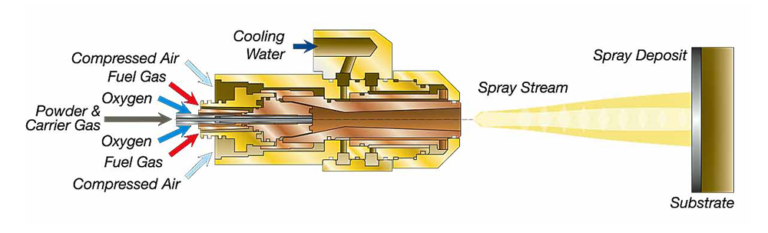

HVOF spraying or high speed spraying provides a wear and corrosion resistant coating to many objects. The technique stands for High Velocity Oxygen Fuel, which means that with this technique a coating or top layer is sprayed at a high particle speed.

The gas stream that expands through a special nozzle (venturi effect) reaches a speed of up to 1500 m/sec. The powder injected axially into this gas stream acquires a very high velocity (up to 800 m/sec). The resulting coatings are characterized by their low porosity and high bonding strength.

Characteristics

- Fine microstructure

- Very dense and low porous layers

- High bond strength

- Very smooth to edit

- Optimal micro-hardness

- Good corrosion properties

- Excellent for applying carbide coatings

- Low oxidation degree

Applications

- Seal raceways against the running-in of the seals

- Ball valves to improve wear resistance and chemical protection

- Hydraulic piston rods in the offshore for seawater protection

- Repairs or dimensional corrections of run-in shaft journals or bearing seats

- Substrate for Thermal Barrier Coatings

- Cavitation protection at hydropower plants

- Pump housings and impellers against chemical attack

Positive features

The biggest advantages of an HVOF sprayed coating are the very low porosity and the high adhesion values. Coatings applied with the HVOF installation, are sometimes also called RAM coatings

Applicable materials (NEN-EN 1274)

Metals & Alloys Steel & Stainless Steel & Molybdenum

Chromium base Cr3C2NiCr also known as Chromium carbide

Cobalt base CoCrW also known as Stellite 1, 6 and 12

Nickel base NiCrMoNb also known as Inconel 625

Nickel base NiCrMoW also known as Hastelloy C

Nickel base NiCrBSi

Fuse alloys NiCrBSi

How can we be of service to you?

Do you have a question? Please contact us by filling in the contact form.